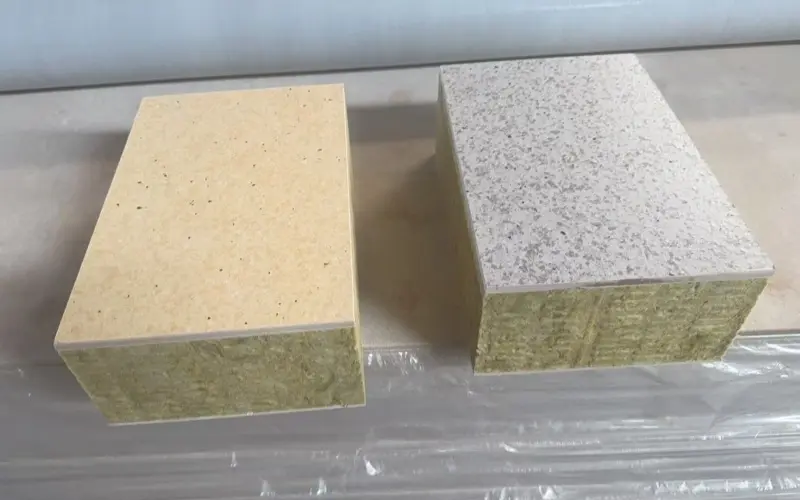

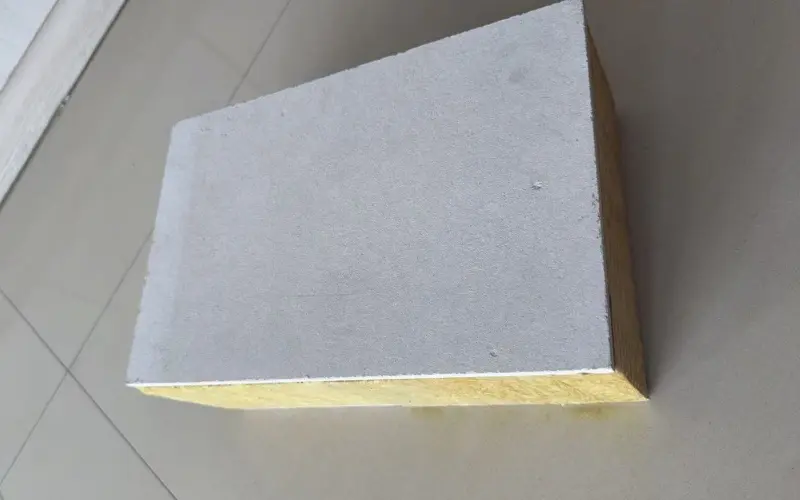

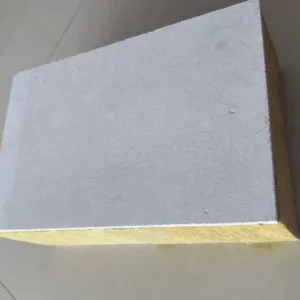

| Product | Fiber Cement Composite Panels |

|---|---|

| Thermal Insulation | Made with EPS particles and lightweight cement core, the panel offers excellent heat insulation, helping maintain a stable indoor temperature. |

| Thermal Preservation | Main materials are anti-freezing, eco-friendly, and designed to reduce energy consumption in various climate conditions. |

| Fire Resistance | Cladded with 4.5mm fiber cement board on both sides, the panel can withstand temperatures over 1000°C for more than 4 hours, certified non-combustible. |

| Water Resistance | Proven through immersion tests: the panel does not absorb water or leak even after 1 year of water exposure, ideal for wet-area applications. |

| Sound Insulation | The EPS polystyrene granules inside the core provide effective acoustic insulation and sound absorption, improving indoor comfort. |

| Ease of Installation | Can be installed quickly using PU foam or cement-based adhesive, suitable for dry construction methods and prefab building systems. |

| Labor & Time Saving | Lightweight and modular design reduces construction time and labor cost, increasing efficiency on-site. |

| High Load Capacity | Allows for direct nailing, supports heavy fixtures, and is compatible with ceramic tiles, wallpaper, and various decorative finishes. |

| Earthquake Resistance | Engineered to resist seismic activity, the system has a quakeproof performance rating over 8.5 (Richter Scale equivalent). |

| Space Saving | Panel thickness ranges from 50mm to 200mm, significantly thinner than traditional blocks, increasing usable floor space while reducing structural weight and cost. |

| Application | Commercial buildings Office buildings Shopping malls and business centers Hotels and hospitality projects Renovation and modular housing |